Call Us

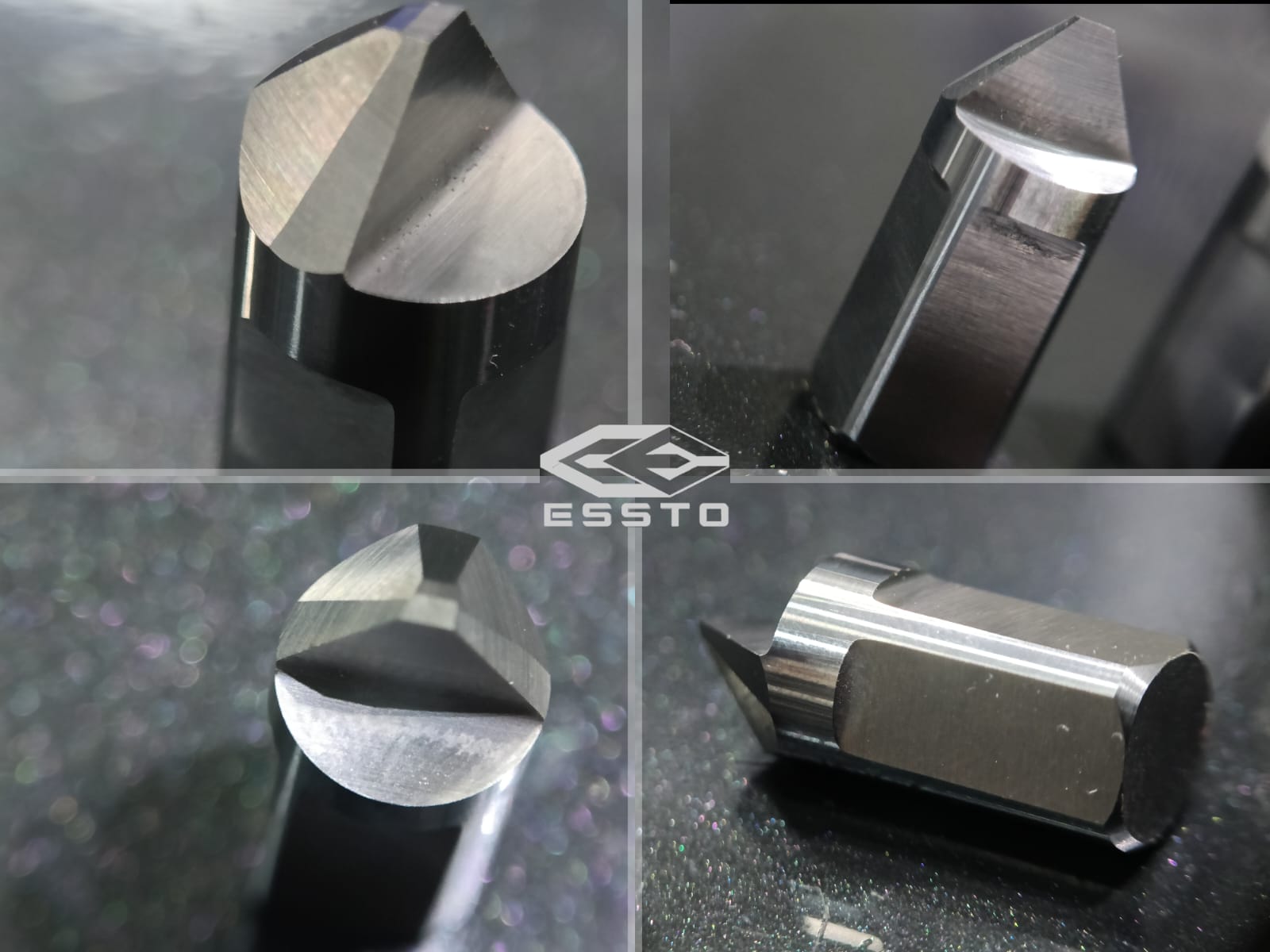

Carbide CNC Notching Tools for HSS Roll Notching

Carbide CNC Notching Tools for HSS Roll Notching Specification

- Cutter Type

- Profile Notching Cutter

- Cutting Accuracy

- 0.01 mm

- Tool Type

- Carbide Notching Tool

- Coating

- Titanium Nitride (TiN) / Uncoated

- Length

- 40 mm - 120 mm

- Coating Type

- PVD Coating / TiN

- Hardness

- 90-92 HRA

- Cutting Force

- High strength, suitable for CNC Notching

- Cutting Speed

- Max 100-150 m/min (as per material)

- Cutting Capacity

- Up to 65 HRC Hardness (HSS Roll)

- Machine Type

- CNC Notching Machine

- Operation Type

- Automatic/Manual as per CNC

- Shape

- Rectangular / Custom CNC Profile

- Operate Method

- CNC Machine Operated

- Material

- Solid Tungsten Carbide

- Diameter

- 6 mm - 20 mm (shank or tool diameter)

- Maximum Torque

- Optimized for high-torque CNC applications

- Processing Type

- Precision CNC Notching

- Shank Type

- Straight precision-ground shank

- Edge Design

- Sharp precision-edged for burr-free notching

- Maintenance

- Requires occasional regrinding

- Temperature Resistance

- Up to 1000°C

- Standards Followed

- ISO 9001:2015 certified manufacturing

- Surface Finish

- Mirror-finish for reduced friction

- Reusability

- Indexable/regrindable for extended tool life

- Application

- For notching and grooving on hardened HSS rolls in metalworking and tube industries

- Packaging

- Individual protective cases with anti-corrosion sealing

- Compatibility

- Universal fit for standard CNC notching tool holders

Carbide CNC Notching Tools for HSS Roll Notching Trade Information

- Minimum Order Quantity

- 10 Number

- Supply Ability

- 500 Per Day

About Carbide CNC Notching Tools for HSS Roll Notching

Find the spotlight in metalworking with our Carbide CNC Notching Tools, engineered for unbeatable precision and potent performance in HSS roll notching. Featuring a sharp, precision-edged design for burr-free notching and mirror-finish surfaces that ensure phenomenal reduction in friction, these tools are popular among industry leaders. Their indexable and regrindable nature offers extended tool life and universal compatibility with standard CNC notching tool holders. Crafted from solid tungsten carbide and certified to ISO 9001:2015 standards, these notching tools deliver high cutting accuracy, potent durability, and resilience up to 1000C, making them a standout solution for demanding tube and metal industries.

High-Efficiency Carbide CNC Notching Tools: Usage and Features

Designed for potent usage in metalworking and tube industries, these Carbide CNC Notching Tools can be operated automatically or manually with CNC machines. Precision-engineered for notching and grooving on hardened HSS rolls, they deliver burr-free results with a mirror-finish edge that minimizes friction. Compatible with various surfaces, the tools feature a straight, precision-ground shank and are optimized for high-torque operations, guaranteeing phenomenal efficiency across rectangular or custom CNC profiles.

Order Terms, Packing, and Export Delivery Convenience

List price is available for bulk orders from dealers, distributors, and exporters. Each Carbide CNC Notching Tool arrives in an individual protective case with anti-corrosion sealing, ensuring safe transit. Order completion is typically efficient, with delivery times adjusted per export market and order volume. As a supplier, trader, or wholesaler in India, we prioritize quick, secure order fulfillment, offering flexible payment terms to accommodate varying business needs.

High-Efficiency Carbide CNC Notching Tools: Usage and Features

Designed for potent usage in metalworking and tube industries, these Carbide CNC Notching Tools can be operated automatically or manually with CNC machines. Precision-engineered for notching and grooving on hardened HSS rolls, they deliver burr-free results with a mirror-finish edge that minimizes friction. Compatible with various surfaces, the tools feature a straight, precision-ground shank and are optimized for high-torque operations, guaranteeing phenomenal efficiency across rectangular or custom CNC profiles.

Order Terms, Packing, and Export Delivery Convenience

List price is available for bulk orders from dealers, distributors, and exporters. Each Carbide CNC Notching Tool arrives in an individual protective case with anti-corrosion sealing, ensuring safe transit. Order completion is typically efficient, with delivery times adjusted per export market and order volume. As a supplier, trader, or wholesaler in India, we prioritize quick, secure order fulfillment, offering flexible payment terms to accommodate varying business needs.

FAQs of Carbide CNC Notching Tools for HSS Roll Notching:

Q: How does the carbide CNC notching tool benefit HSS roll notching operations?

A: These tools offer unbeatable sharp edges for burr-free notching, mirror-finish surfaces to reduce friction, and high hardness for potent durability, resulting in precise performance and extended tool life.Q: What types of machines are compatible with these notching tools?

A: They are universally designed to fit standard CNC notching tool holders and can be operated with both automatic and manual CNC machines.Q: When is regrinding or indexing required for the carbide CNC notching tool?

A: Occasional regrinding or indexing is recommended to maintain cutting accuracy and extend tools service life, especially after extensive usage or visible wear.Q: Where are these carbide CNC notching tools manufactured and shipped from?

A: They are manufactured in India under ISO 9001:2015 standards and shipped globally, with packaging tailored for safe export to any market.Q: What is the process for placing an order and securing delivery?

A: Contact your supplier, distributor, or trader for list price and payment terms. Once the order is completed, the tools are packed in anti-corrosion protective cases for fast, secure delivery as per market requirements.Q: How does the mirror-finish surface enhance tool performance?

A: The mirror-finish promotes reduced friction during notching and grooving, leading to smoother operation, minimized heat build-up, and enhanced cutting efficiency on HSS roll surfaces.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Carbide Notching Tools Category

Carbide CNC Notching Tools for Other Rolls

Price 170 INR / Number

Minimum Order Quantity : 10

Usage : Industrial

Hardness : High

Features : HSS

Tool Type : CNC machine Tool

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send Inquiry

Send Inquiry

Call Me Free

Call Me Free