Call Us

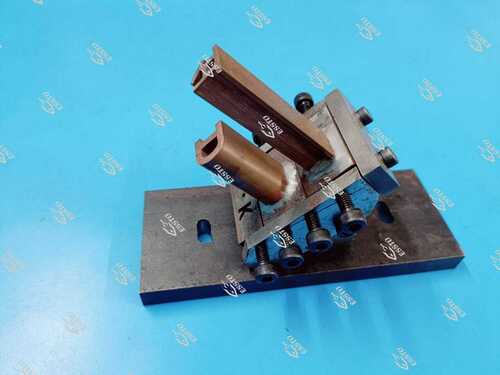

Section Mill ECP

Price 12000 INR/ Piece

MOQ : 1 Number

Section Mill ECP Specification

- Application

- Industrial, Heavy Duty Section Rolling

- Tool Type

- Mill Machine

- Spindle Speed

- 1800 rpm

- Cutting Speed

- 16-22 m/min

- Power Source

- Electric

- Noise Level

- Below 75 dB

- Product Type

- Section Mill

- Material

- Steel

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Drive Type

- Electric

- Voltage

- 380V

- Weight (kg)

- 2200 Kg

- Dimension (L*W*H)

- 3800 x 1200 x 1800 mm

- Capacity

- 2 - 3 ton/hr

- Feature

- High Efficiency, Rugged Construction

- Color

- Blue

- Input Material Thickness

- 5 mm - 25 mm

- Section Size Range

- 100 mm to 400 mm

- Lubrication System

- Centralized Automatic

- Surface Finish

- Painted

- Motor Power

- 32 kW

- Installation Type

- Floor Mounted

- Cooling System

- Integrated Water Cooling

- Roller Material

- Alloy Steel

- Minimum Order Quantity

- 1 Unit

- Operating Temperature

- -10°C to 50°C

- Roller Diameter

- 300 mm

About Section Mill ECP

The Section Mill ECP stands out as a robust machining tool acclaimed for its precision in cutting and shaping metal sections. Its durability and advanced cutting technology guarantee high efficiency and accuracy. Widely employed in construction, engineering, and manufacturing, it excels in milling, drilling, and shaping structural components. With innovative features, it caters to diverse section sizes and materials, significantly enhancing productivity and quality in metal fabrication. Its reliability and performance make it an indispensable asset in modern industrial operations, ensuring precise and efficient machining outcomes.

Advanced Automation for Efficient Rolling

With a fully computerized PLC control system and automatic grade operation, this Section Mill ECP simplifies and accelerates the section rolling process. Operators benefit from precise adjustments, consistent output quality, and ease of use, enabling faster and more reliable industrial production.

Rugged Construction and Heavy-Duty Performance

Engineered with high-strength steel and alloy steel rollers, this mill is designed for harsh industrial environments. Its integrated water cooling and centralized lubrication systems minimize wear and maximize uptime, ensuring a long service life under continuous operation.

Customizable for Diverse Heavy Industrial Needs

Supporting section sizes from 100 mm to 400 mm and material thicknesses of 525 mm, the mill is highly versatile. Suitable for a variety of production requirements, dealers, exporters, and manufacturers can adapt it for a range of section rolling tasks with minimal downtime.

FAQs of Section Mill ECP:

Q: How does the centralized automatic lubrication system in the Section Mill ECP enhance machine longevity?

A: The centralized automatic lubrication system ensures that all critical moving parts receive consistent lubrication, reducing friction and wear. This extends component life, minimizes manual maintenance intervals, and contributes to reliable, long-term operation.Q: What is the recommended operating environment for this section mill?

A: This section mill is designed to operate efficiently in ambient temperatures ranging from -10C to 50C, making it suitable for diverse industrial environments across India and beyond.Q: When should integrated water cooling be used during production?

A: Integrated water cooling operates continuously during section rolling to dissipate heat generated by the 32 kW motor and friction from the alloy steel rollers. This safeguards the mills components and maintains optimal performance during long production cycles.Q: Where can the Section Mill ECP be installed in an industrial facility?

A: Designed for floor mounting, the Section Mill ECP must be installed on a stable, level surface within industrial production areas. It requires accessible space for safe operation, maintenance, and material handling, as specified by its footprint dimensions (3800 x 1200 x 1800 mm).Q: What benefits does the automatic PLC control system provide for industrial users?

A: The PLC control system offers precise, programmable management of mill functions. Users enjoy improved accuracy, reduced human error, streamlined operation, and easier coordination with other automated processes, increasing efficiency and output consistency.Q: How is safety ensured during operation of the Section Mill ECP?

A: Safety is maintained through features such as low noise levels (below 75 dB), painted surface finish for easy cleaning, and integrated control systems with emergency stop functions, ensuring operator well-being and regulatory compliance.Q: What types of steel material can be processed with this mill?

A: The Section Mill ECP is engineered to handle a wide range of steel materials, with input thicknesses from 5 mm to 25 mm, accommodating varied industrial requirements for heavy-duty section rolling applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send Inquiry

Send Inquiry