Call Us

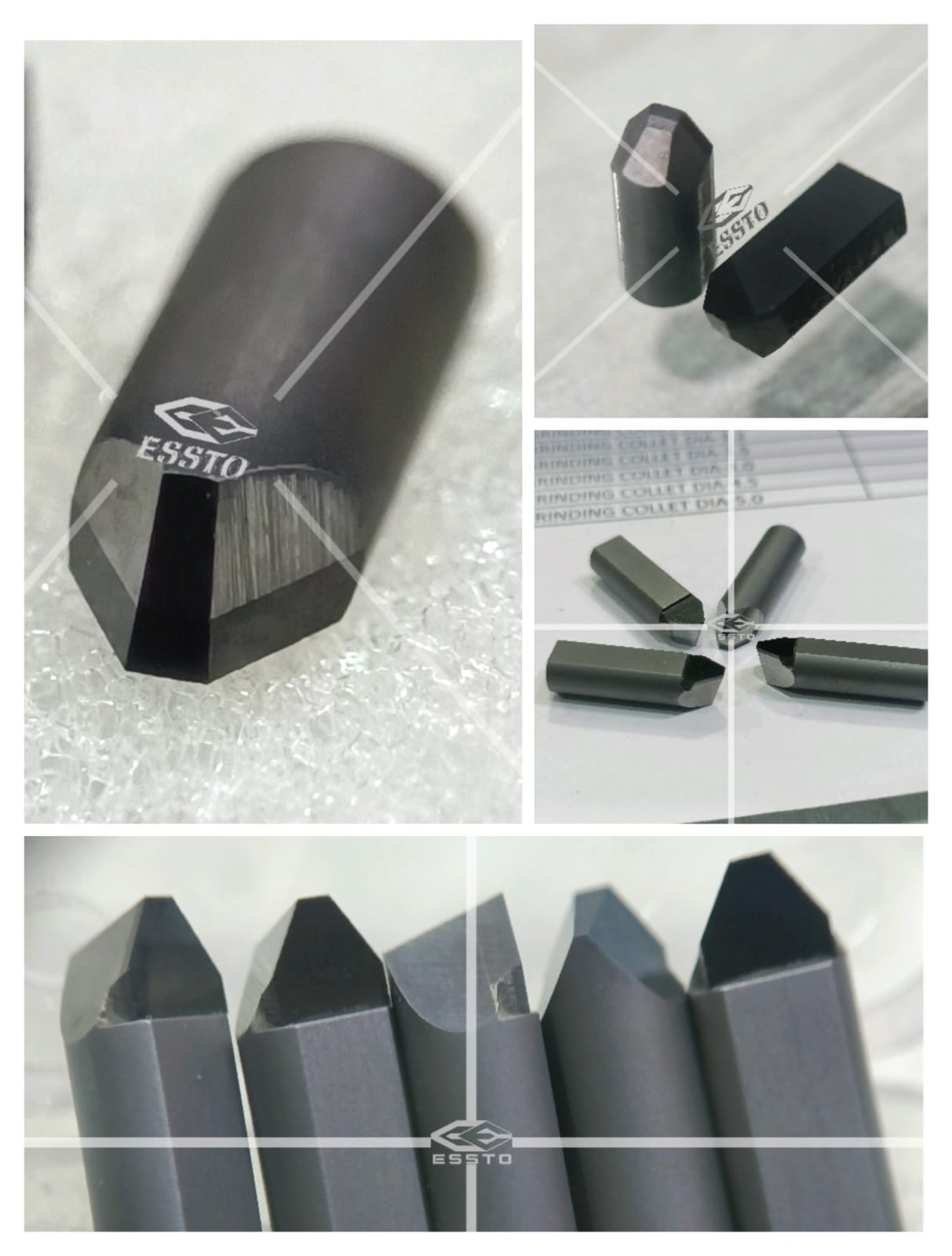

PCD Notching Tools For T.C Roll Notching

MOQ : 1 Number

PCD Notching Tools For T.C Roll Notching Specification

- Coating Type

- Uncoated / As Per Order

- Coating

- NA / Diamond PCD

- Length

- Customized

- Shape

- Customized/Rectangular

- Operate Method

- Mechanical

- Machine Type

- Roll Notching Machine

- Cutting Accuracy

- 2 micron

- Cutting Capacity

- High Efficiency for T.C Roll

- Cutting Force

- High

- Tool Type

- Notching, Grooving Tool

- Cutter Type

- PCD (Polycrystalline Diamond)

- Drill Bits Types

- PCD Notching Tool

- Operation Type

- Manual or Automatic

- Brooches Type

- Roll Notching Broach

- Features

- Ultra-Precision, Long Life, Wear Resistance

- Material

- PCD Tip, Carbide or Steel Body

- Cutting Speed

- Max 150 m/min (Depending on Material)

- Hardness

- 98 HRa (PCD) / > 1600 HV

- Diameter

- Customized (Contact for Details)

- Maximum Torque

- Customizable as per Application

- Processing Type

- Precision Notching

- Customization

- Available for varying roll profiles

- Chipping Resistance

- High due to PCD edge

- Regrinding Service

- Available from Manufacturer

- Application

- Tungsten Carbide (T.C) Roll Notching

- Edge Tolerance

- < 0.01 mm

- Compatibility

- Suitable for all standard roll notching machines

- Maximum Feed Rate

- 0.15 0.5 mm/rev (Depending on setup)

- Service Life

- Up to 20x conventional tools

- Temperature Resistance

- Suitable for high-temperature operations

- Surface Finish

- Superior (Mirror-like) finish

PCD Notching Tools For T.C Roll Notching Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 50 Per Day

About PCD Notching Tools For T.C Roll Notching

PCD (Polycrystalline Diamond) Notching Tools for T.C. (Tungsten Carbide) Roll Notching are specialized instruments designed for precise and efficient notching of tungsten carbide rolls used in various industrial applications. These tools typically feature a diamond-tipped cutting edge, offering exceptional hardness and wear resistance. Their shape and construction ensure accuracy and longevity, even when working with tough materials. Used primarily in industries such as steel manufacturing, automotive, and aerospace, they facilitate the creation of precise notches on T.C. rolls, essential for enhancing product quality and performance. With their superior cutting ability and durability, PCD notching tools are crucial assets in machining operations demanding high precision. All diameters are available with us.

Ultra-Precise Notching for T.C Rolls

Our PCD Notching Tools deliver mirror-like finishes and precision up to 2 microns, making them perfect for Tungsten Carbide roll notching. The ultra-sharp PCD edge ensures minimal chipping, consistent high performance, and durability across a wide range of notching applications, whether for manual or automated setups.

Enhanced Durability and Longevity

Experience up to 20 times longer service life compared to standard tools. The PCD composition guarantees high wear resistance and stability even in high-temperature environments, significantly reducing tool replacement and downtime. Superior edge retention yields reliable results over extended operational periods.

Customization and Versatility

We offer tailored solutions for varying roll profiles and applications, including customizable tool diameters, lengths, shapes, and torque settings. Compatible with all standard roll notching machines, our tools are suitable for various industries and processing requirements, supported by a comprehensive regrinding service in India.

FAQs of PCD Notching Tools For T.C Roll Notching:

Q: How are PCD Notching Tools used for Tungsten Carbide roll notching?

A: PCD Notching Tools are specifically designed for precision notching and grooving of Tungsten Carbide rolls. Simply install them in any standard roll notching machine, either manual or automatic, to achieve accurate and superior notching results with minimal chipping and high efficiency.Q: What makes these notching tools different from conventional options?

A: These tools feature PCD (polycrystalline diamond) tips and boast extreme hardness (98 HRa, >1600 HV), leading to ultra-precision, increased wear and chipping resistance, and a mirror-like surface finish. Their lifespan extends up to 20 times that of traditional tools, offering greater efficiency and reduced downtime.Q: When should I consider regrinding or replacing the tool?

A: Regrinding is recommended when you notice a decline in surface finish quality or increased cutting force during notching. The manufacturer provides professional regrinding services, ensuring your tool regains its original performance without needing immediate replacement.Q: Where can I purchase or get support for these tools in India?

A: PCD Notching Tools are available from authorized dealers, distributors, and manufacturers across India. Full support, including customization and regrinding services, is provided by trusted suppliers and service providers nationwide.Q: How do I select the right tool configuration for my specific application?

A: Tool selection depends on your roll profile, machine specifications, and desired finish. Customization options such as diameter, length, edge profile, and maximum torque are availablecontact your supplier or manufacturer with your requirements for an optimal solution.Q: What are the main advantages of using PCD Notching Tools for T.C rolls?

A: These tools deliver ultra-precision, high efficiency, vastly extended tool life, minimal chipping, superior surface quality, and reliable performance even in high-temperature operations, making them highly cost-effective for industrial notching applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send Inquiry

Send Inquiry